As a high school student, Michael Adams loved chemistry but found it rather dry. Then one day his science teacher lectured about vitamins, particularly vitamin A, which has a crucial role in human eyesight. When light strikes a form of vitamin A in the retina, the molecule rhodopsin is chemically rearranged, triggering a nerve response that enables color vision, and sight in a dim-light environment.

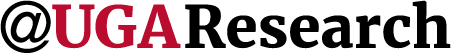

“I was enthralled,” says Adams, Georgia Power Professor in Biotechnology and Distinguished Research Professor in the Department of Biochemistry and Molecular Biology. “I can still remember the moment now. That day when chemistry was put in a biological context, especially at the molecular level—it made worlds come together for me, and it still does.”

Biochemistry remained his academic passion through high school in England and at King’s College, University of London, where he received his B.S. and then Ph.D. in 1979. His doctoral research focused on enzymes known as hydrogenases that generate hydrogen gas. Today, hydrogen gas is used increasingly as a zero-carbon fuel source.

“At the time, people were trying to characterize these hydrogenase enzymes, but no one understood how they make hydrogen gas, and that captivated me,” Adams says.

His next stop was a postdoctoral position at Purdue University.

“We learned at Purdue that metals—iron and nickel—were the keys to catalyzing hydrogen production by these enzymes.”

In 1981, Adams began working for Exxon in New Jersey on hydrogenases from conventional soil bacteria.

“Exxon was interested in the same metals that I studied at Purdue because they are also used as catalysts in the oil industry. Biomimetics was an emerging field at the time. The idea was to chemically synthesize catalysts based on knowledge of what nature had produced after billions of years of evolution. In this case, the chemical catalyst would contain iron and nickel and would produce hydrogen as a fuel. However, to do this, you first had to answer the question, ‘How do these hydrogenase enzymes work at the atomic level?’”

Adams returned to academia in 1987, joining the university’s Franklin College of Arts and Sciences.

“At UGA, I established a research program looking at hydrogenases and other types of metal-containing enzymes from remarkable microorganisms—hyperthermophiles. These grow in volcanic vents near 100 degrees Celsius and had just been reported in the scientific literature. Little was known about them at the time. But when they grew, some produced hydrogen gas, so we knew they must have hydrogenase enzymes and that those enzymes must be exceptionally stable to work at 100 degrees C. We’ve come a long way and now have a really good idea of how these microbes work, how many of their enzymes work, and how some of their enzymes produce hydrogen.”

To date, Adams’ research program has produced more than 400 published studies and several patents.

About a decade ago, Adams’ research began shifting to also address evolutionary and applied questions. For the basic research, he began a new line of inquiry with his model hyperthermophile microbe Pyrococcus furiosus—“furious” or “rushing fireball”—which he has been working with since it was discovered in 1986 in hot sea vents.

“These organisms use respiration mechanisms involving two enzymes that we call MBH and MBS, that are very early versions of an enzyme that humans use to breathe,” says Adams.

MBH and MBS allow Pyrococcus to breathe by producing either hydrogen gas or hydrogen sulfide gas in the hot-vent environment where gases and extreme temperatures are similar to conditions on Earth billions of years ago.

“We are getting a glimpse back into the past, providing insight into how our own respiratory system evolved and how it works.”

In the applied work, Adams and his colleagues are exploring yet another hyperthermophile microbe that also produces hydrogen gas, Caldicellulosiruptor bescii, but in this case he is using it to break down plant biomass and generate other fuels as well as industrial chemicals, rather than hydrogen. The goal of this research is to develop sustainable plant-based fuels or chemicals to supplement and eventually replace petroleum-based chemicals and fuels.

Some non-food plants—switchgrass and poplar trees—are excellent candidates for sustainable biofuel and chemicals production. Switchgrass, for instance, is a perennial grass native to North America grown on marginal farmlands with minimal need for agricultural chemicals. But switchgrass and poplar are very tough and are typically broken down using high-temperatures and harsh, expensive chemicals.

Adams and his colleagues were looking for alternatives to that process. They found a potential solution in the hyperthermophile C. bescii, which they discovered grows well on the natural untreated biomass of switchgrass and poplar. In its purified form, C. bescii efficiently breaks down the unprocessed plants and can be engineered to use the plant sugars and convert them to fuels and chemicals.

“This microbe can utilize all of the types of sugars in these plants, which are mainly cellulose and hemicellulose,” says Adams. “Although several microorganisms can utilize cellulose, it is rare for a microbe to also use the hemicellulose.”

In a recent study published in Nature, Adams and colleagues showed that C. bescii genetically engineered by his group had almost completely broken down a genetically engineered form of poplar to make ethanol, a fuel that is a gasoline additive.

“The microbe only used about 20% of the sugars in ‘normal’ poplar to produce ethanol, but more than 90% in the new plant strains,” says Adams.

The research was conducted in collaboration with plant biologists and biochemical engineers at North Carolina State University and funded by the U.S. Department of Energy.

This new study could point the way to local and sustainable biofuels and chemical production.

“I think someday we’ll see instances of local farmers growing new transgenic strains of poplar or switchgrass, which would be harvested and put into a local plant biomass mill with a genetically engineered microbe and processed to yield a fuel or an industrial chemical,” he says. “This is a promising direction for producing renewable, plant-based chemicals or fuels to replace non-renewable petroleum-based chemicals and fuels. Fossils fuels are a finite resource, and before they run out in the coming decades, we must develop a sustainable fuel and chemical supply.”