Researchers in UGA’s College of Engineering are looking for ways to make sure that plump, fresh blueberries make it to supermarket shelves without getting mangled in the process.

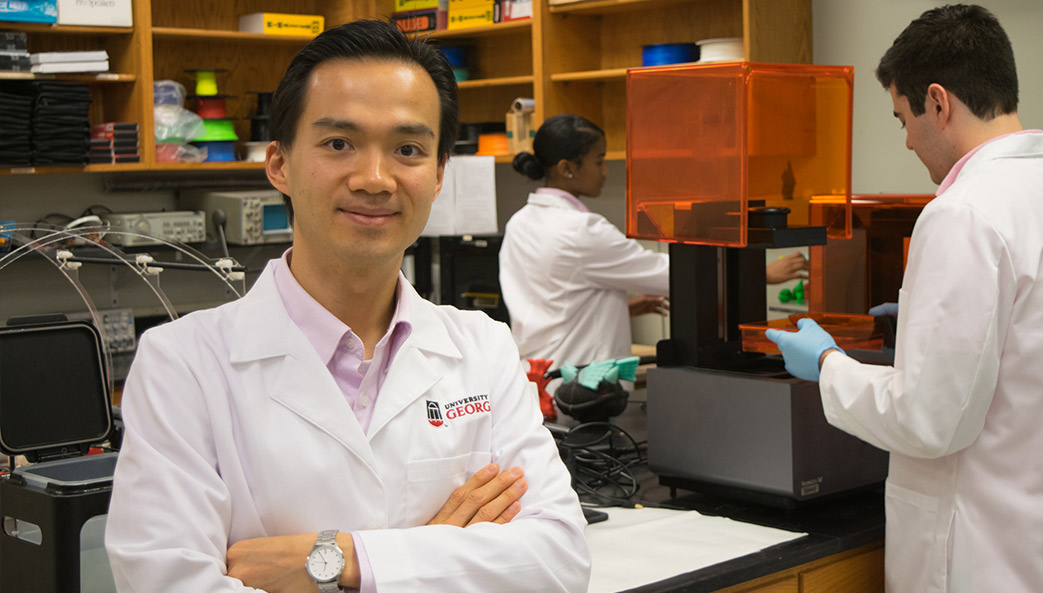

Changying “Charlie” Li, an associate professor who specializes in sensor technology, is leading a multidisciplinary team from 10 institutions across the nation to develop an affordable harvest-aid system and sensor technologies that will reduce labor costs and improve harvest efficiency.

The Li team’s key design features include a unique catching and conveying system. As the machine rolls along rows of blueberry bushes, an accompanying worker with a specially designed “shake stick” shakes each bush and its ripe berries fall onto the catch plate. To protect the berries as they fall, the machine generates a gentle cushion of air, like that of an air hockey table. Specially designed sensors will measure the damage blueberries experience so researchers can fine-tune the system.

Until now, “nearly all fresh market blueberries have had to be harvested entirely by hand because traditional machine harvesters damage the fruit so much that its quality is too low to be sold directly to consumers,” Li said.

The lower-quality fruit ends up in processed foods such as blueberry bagels or blueberry pancake mix. According to Li, these berries often bring farmers as little as half the price of the higher-quality handpicked fruit.